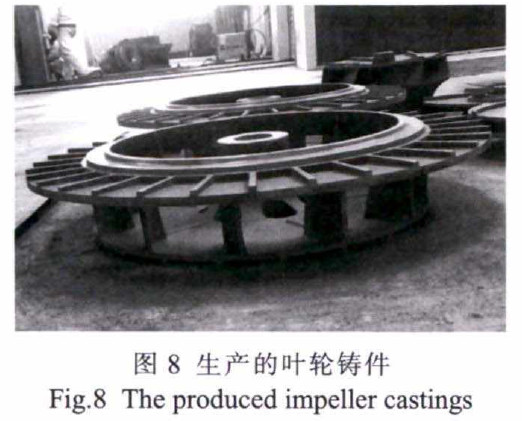

Resin sand casting is widely used in the manufacturing of medium and large impeller blanks because it has high forming precision and high adaptability to complex structures. Directly cast impellers have surface defects like pores, sand inclusions, and cold shuts, and the size precision and surface roughness are difficult to guarantee that they meet assembly and dynamic balance standards and must be sent for additional finishing processing.

Introduction

Because the impeller is the principal unit in fluid machinery such as pumps, compressors, and fans, precision of geometry, surface quality, and quality of dynamic balance of the impeller are crucial to the seamless operation of equipment. As accuracy in impeller casting becomes an ever-increasing requirement, resin sand casting has increasingly developed into the method of choice in producing medium and large impeller blanks. Resin sand casting has good forming accuracy, flexibility to complex structures, and lower cost. But the resin sand casting also has defects such as high surface roughness, sand inclusions, porosity, and cold shuts, leading to dimension accuracy that cannot satisfy the requirements of subsequent assembly and dynamic balance. So, the finishing process link is very crucial in the manufacturing process of resin sand cast impellers.

While the conventional finishing processing technique is capable of enhancing the quality of castings to a certain degree, issues like low efficiency and unstable technology still haunt the production process. For a boost in production efficiency and quality of processing, it is imperative to conduct systematic improvement of current finishing technology.

Difficulties in Finishing Processing of Resin Sand Cast Impellers

During the production of complicated structure impellers, resin sand casting is greatly applied in aviation, energy, and high-grade equipment manufacturing industries due to its highly flexible forming and strong adaptability. However, due to the effect of the characteristics of the casting process itself, resin sand castings face many technical challenges in the subsequent finishing processing stage. Especially in surface quality, precision, and stability of processing, these impeller parts are more troublesome than machined parts. The following introduces the typical problems during their finishing process from four key points.

Difficulty in Processing Complex Flow Channel Structures

Resin sand cast impellers have complex three-dimensional flow channel structures and curved surface envelopes, especially closed blades or asymmetrically distributed guide channels, with numerous blind areas and small spaces. Under such geometrical circumstances, pneumatic grinding, mechanical hand filing, and other processes struggle to enter the flow channel interior or back of the blade to effectively eliminate flash, burrs, and sand inclusion residue. In addition, the curved surface is difficult to accommodate the processing tool, readily leading to local over-grinding or dross, which affects the product’s appearance quality and flow properties as well as being one of the technical hurdles of the current finishing process.

Large Dimensional Deviation of Castings

The size stability of resin sand casting is determined by a variety of factors such as thermal expansion, variation of shrinkage rate, and sand mold strength. Even when the mold design is precise, the resultant formed impeller typically contains large contour deviation or uneven surface profile. The deviation makes the finishing processing not only have strong margin removal capability but also need to include three-dimensional detection or comparison models for compensatory processing strategy. While maintaining accuracy in major dimensions and contours, control of the amount being removed is also required so as not to compromise blade strength, which poses greater demands on process design.

Uneven Surface Hardness

During casting, owing to defects such as cold shuts, slag inclusions, or local overburning, non-uniform hardness distribution areas are created on the surface of the impeller. For example, the boundaries of some blades have hard shells of local overheating, and they are significantly greater than the other areas’ matrix hardness, and the cold shut areas may even have soft spots of weak strength. Such hardness variation not only aggravates the tool wear in the process of processing but can even cause abrupt change of cutting load, resulting in quality defects such as surface tearing, scratching, or micro-cracks, which seriously affects finishing stability and subsequent surface treatment quality.

Poor Consistency of Manual Processing

Although manual cutting is unavoidable in some remote area, its operation is greatly dependent on the experience and level of workers and hence plagued with consistency problems such as uneven processing depth, abnormal trimming marks, and (unsmooth) curved surface transition. In particular in mass production of impellers, manual operation is hard to realize standardized control, not only inefficient but also hard to be compatible with the digital quality detection system, and become the main hindrance limiting the controllability and automation of modern finishing processing quality.

Overview of Traditional Finishing Process Flow

The traditional finishing process flow generally involves the following steps:

- Coarse grinding/filing (manual) to remove flash

- Sand blasting/shot blasting to clean the surface oxide layer

- Manual grinding of flow channels and blade backs

- Fitter inspection and repair

- Local manual polishing/dynamic balance treatment

These traditional processes have low investment and low operational complexity, but they are low in efficiency, high in labor intensity, and of poor consistency. Since precise and automatic manufacturing is needed for modern manufacturing, traditional processes cannot follow up with production needs step by step. So it is urgent to bring in higher-level finishing processes to further enhance quality and reduce costs.

Improvement Measures for Finishing Processing Technology

Final processing is an essential step in producing complicated impellers, aircraft parts, or high-performance castings to ensure the ultimate geometric precision, surface finish, and service quality of parts. But traditional finishing processes naturally have limitations such as low efficiency, low consistency, and reliance on experiential skill, which cannot meet the multiple requirements of high consistency, high accuracy, and high beat requirements of modern manufacturing. For this end, we suggest the following four systemic improvement measures in regards to equipment upgrade, process re-engineering, and digital integration and strive to realize the transition from “experience-based trimming” to “intelligent finishing”.

Introduction of Five-Axis (Linkage) CNC Processing System

Those hard-to-machined complex curved surface areas (such as leeward surface of impeller and transition zone of blade root) are the weak link in traditional finishing processes. The use of a five-axis linkage CNC machining system is able to maintain the optimal contact angle between the workpiece and the tool under the condition of continuous high-precision trimming in the area of curvature change. By three-dimensional scanning of the component after casting to construct the actual forming model and generating a personalized tool path in the CAM software, the removal amount is more accurate and interference control is more perfect. On a five-axis CNC finishing process of a turbine casting, the surface roughness after finishing was brought down from original Ra6.3μm to as low as Ra2.8μm, while consistency in processing was boosted quite notably, and the scrap rate decreased by more than 65%.

Application of Plasma Cleaning and Precision Sand Blasting Technology

The as-cast surface is generally bonded by oxides, release agent residues, and micro-particles, which would affect subsequent mechanical processing and surface treatment if they are not cleaned up. Plasma cleaning technology relies on high-temperature plasma cracking the pollution and can be used for pretreatment of complex cavities and micro-blind holes. After cleaning, it is combined with low-pressure ceramic bead sand blasting, which has the ability to significantly increase the surface density and micro-profile without damaging the base material, providing an improved basis for subsequent coating or detection. In my view, the combined solution is particularly outstanding in such applications as deburring complex shell components and trimming aviation guide vanes, significantly improving the surface functional performance of products.

Intelligent Deburring and Edge Trimming

The manual deburring process is limited by the ability of operators, and problems such as over-grinding or missing are most likely to occur. We propose that an industrial robot platform with a force feedback control system be introduced. With an adaptive grinding algorithm and a terminal flexible tool, it can automatically adjust the contact force under different working conditions in order to maintain consistency of deburring quality. In the meantime, equipped with a 3D vision recognition system, it can automatically identify flash features, acute angle features, and ridge features and selectively trim particularly in parts, hence satisfying the two requirements of “edge preservation” and “deburring”. It is shown to have remarkable application effects on gas turbine impellers and high-pressure casings, etc., and the burr residue rate per piece is controlled below 2%.

Establishment of Digital Measurement and Feedback Mechanism

Measurements such as shape and position accuracy and surface deviation upon completion need quantitative techniques to verify. The global digital model is measured through a laser scanning system, white light interferometer, or blue light three-dimensional measuring instrument, and compared with the original CAD model to automatically generate a difference chromatogram and deviation data set. This not only can be used for rework automatic judgment and path compensation but also can be fed back to the CAM system for enhancing the next round of tool path strategies, creating a closed-loop chain process of “measurement-analysis-trimming-validation”. In practice, we found that after the implementation of this mechanism, the shape consistency error of the manufactured products converged from ±0.35mm to ±0.08mm, and the rework rate reduced by more than 50%.

Verification of Actual Application Effects

After implementing the above improved process in a fan manufacturing enterprise, relevant data show that:

| Project | Traditional Process | Improved Process |

| Total finishing man-hours (per piece) | 4.5 hours | 2.1 hours |

| Surface roughness (Ra) | 10~12.5 μm | 3.2~6.3 μm |

| Flash/burr residue rate | About 8% | <1% |

| Degree of manual dependence | High | Medium~Low |

| Processing consistency standard deviation (mm) | ±0.25 | ±0.08 |

The upgraded process has significantly improved productivity efficiency, removed manual reliance, improved the accuracy and consistency of the impeller surface, and reduced costs. In general, the upgraded process not only improves processing quality and efficiency but also provides top-level support for intelligent and automated production for enterprises.

Conclusion

Development of the resin sand cast impeller finishing process technology not only symbolizes the enhancement of typical manual processes but also a concrete step towards smart and automated manufacturing. With the implementation of high-technology methods such as five-axis CNC machining, plasma cleaning, robot grinding, and digital measurement feedback, finishing processing efficiency, quality, and consistency have become significantly elevated.