Impeller Prototype Machining

Bring your ideas to life with prototyping

Join hands with us and move forward together.

As a prototype expert of impeller machining, our confidence comes from our hard work and strength.

With 15 years of dedicated expertise in impeller machining and a presence in over 150 countries, our experience and technology have been continuously expanding.

From 3D drawings to programming and debugging, and onto prototype machining, we possess a complete in-house production chain at our factory.

We specialize in a variety of impeller prototyping and precision manufacturing technology, providing CNC machining, 3D printing, and sheet metal processing.

Impeller Prototype Machining

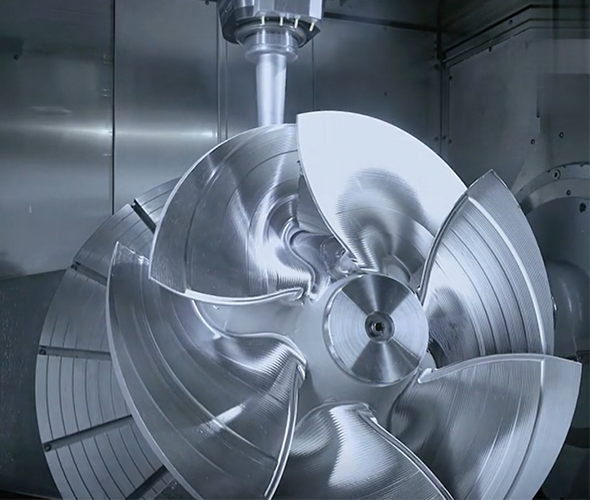

Comprehensive CNC Machining

By combining the collaborative efforts of 3-axis, 4-axis, and 5-axis CNC machines, the unique strengths of each can be fully utilized to efficiently, precisely, and cost-effectively manufacture impellers.

Tight precision requirements

A turbine blade precision of up to 0.01 millimeters is a critical benchmark in high-end manufacturing, achieved through advanced processes, precise inspection, and stringent quality control.

Mass production and supply

Mass production of high-precision turbine blades relies on automation, standardized processes, and strict quality control, achieving efficiency through scale and optimized supply chains.

Highly Skilled Hand-Polishing

Meticulous handcrafted techniques achieve exceptional surface finishes and customization. Though time-consuming and costly, they are essential in industries requiring high precision and aesthetics.

The Balance Between Dynamics and Aesthetics

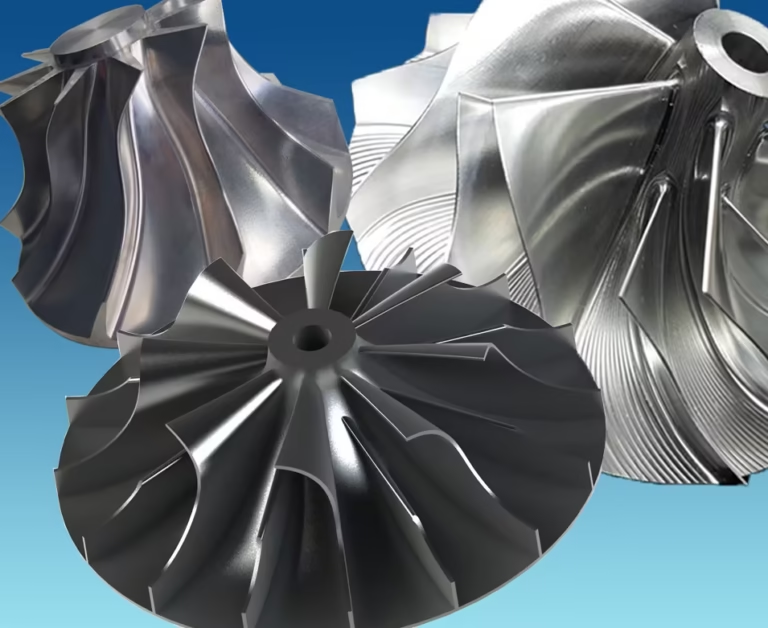

Types of Impellers Processed by Kesu

Various types of impellers are designed for different applications. Open impellers, though prone to faster wear, are ideal for handling low-viscosity fluids. Semi-open impellers can accommodate liquids containing small solid particles, while closed impellers offer high efficiency when pumping clean liquids. Double-suction impellers, designed to balance hydraulic pressure, enable higher flow rates. Axial flow impellers are best suited for scenarios requiring high flow and low head, whereas mixed flow impellers integrate both radial and axial flow properties. Radial flow impellers, on the other hand, are used in high-head pumps. Due to their intricate design and strict precision demands, closed and double-suction impellers pose greater machining challenges.

Vortex Impeller

The blade shape is relatively complex, and to ensure wear resistance, surface strengthening treatments (such as heat treatment or coating) are often applied.

Radial Impeller

For impellers with high precision requirements, the blades are usually arranged radially, demanding high manufacturing accuracy and dynamic balance.

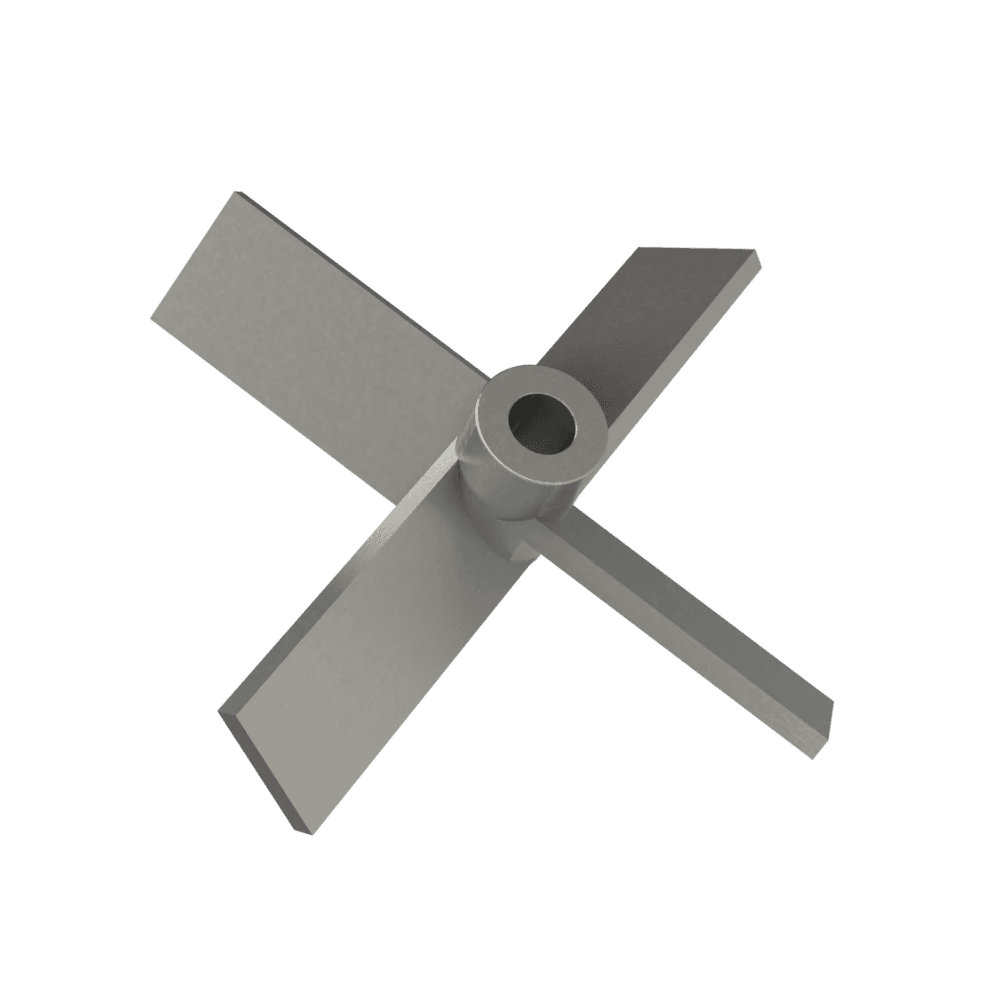

Open Impeller

The production process involves CNC machining or precision casting to ensure blade accuracy, followed by surface treatment to enhance corrosion resistance.

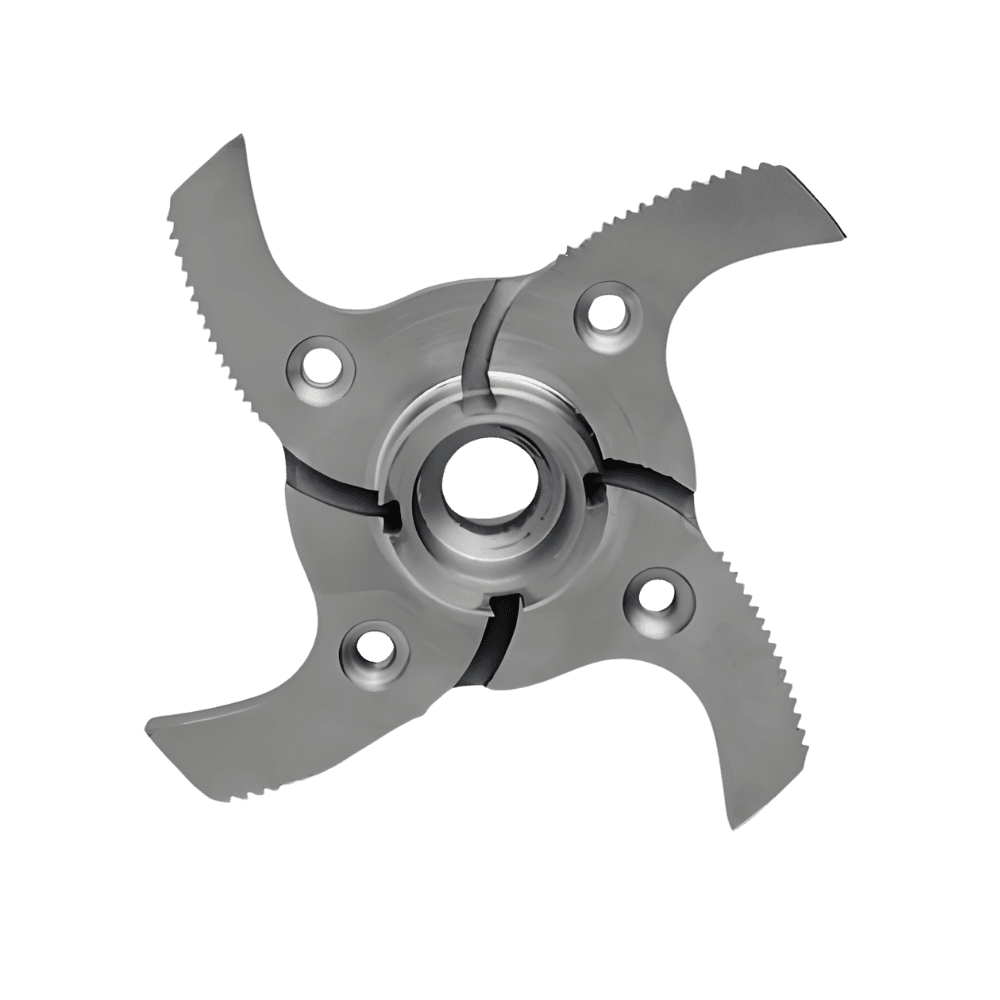

Cutter Impeller

The cutter impeller, made from high-hardness alloys, features sharp edges for cutting fibers. It is cast or forged, then hardened for durability and efficiency.

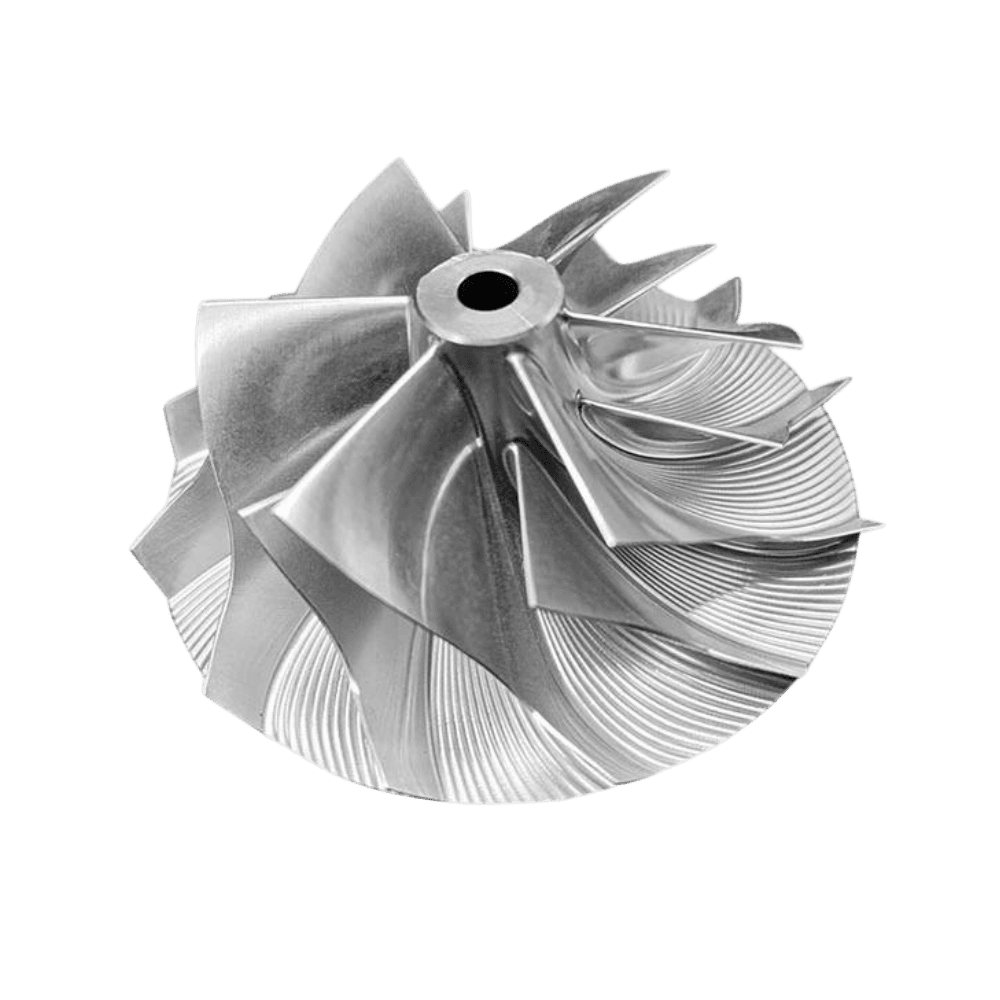

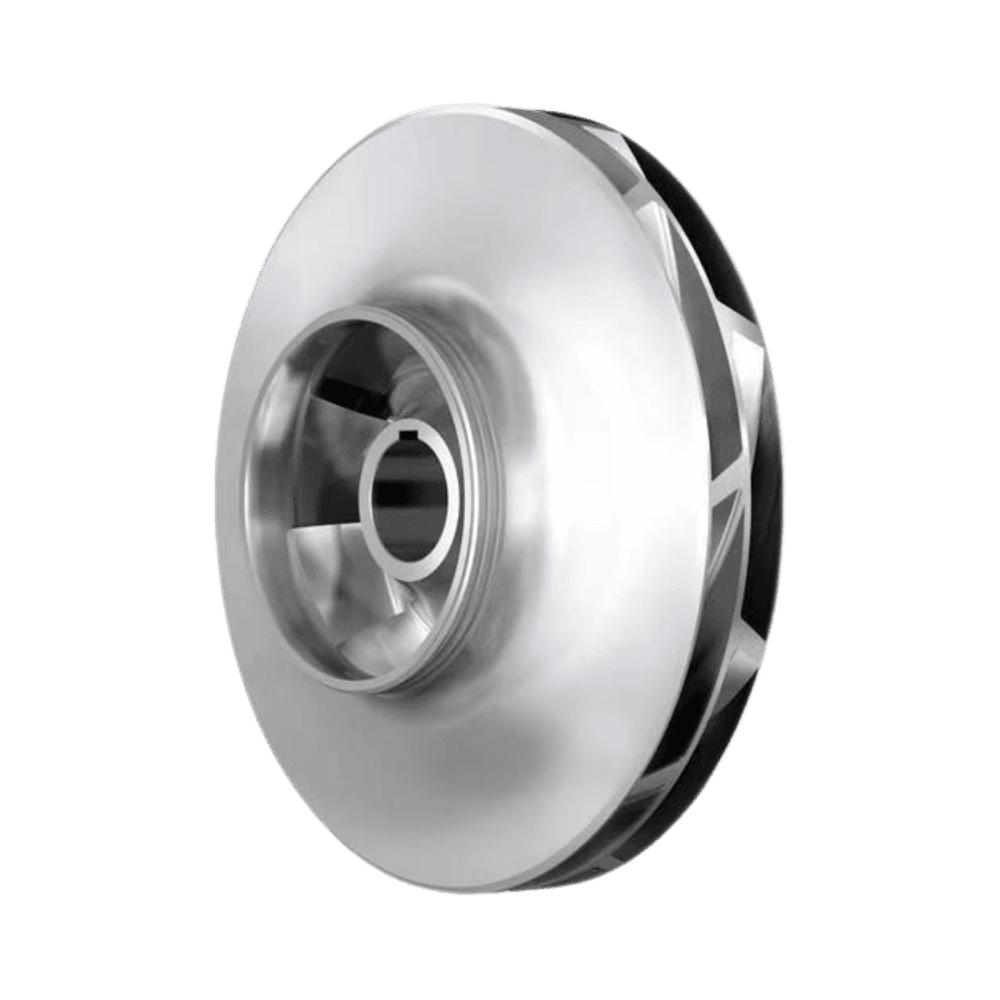

Closed Impeller

Since the blades are enclosed between the front and rear covers, efficiency is high, but machining is difficult and usually requires five-axis CNC for precision.

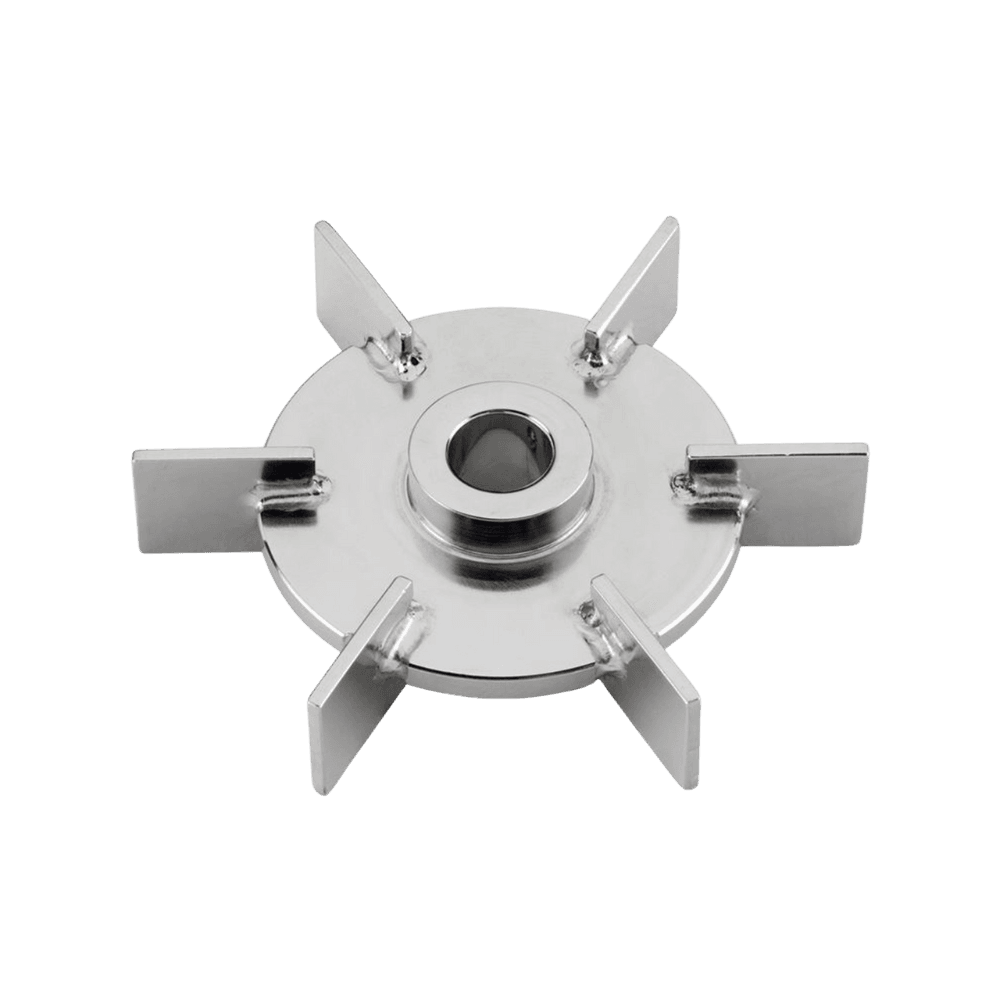

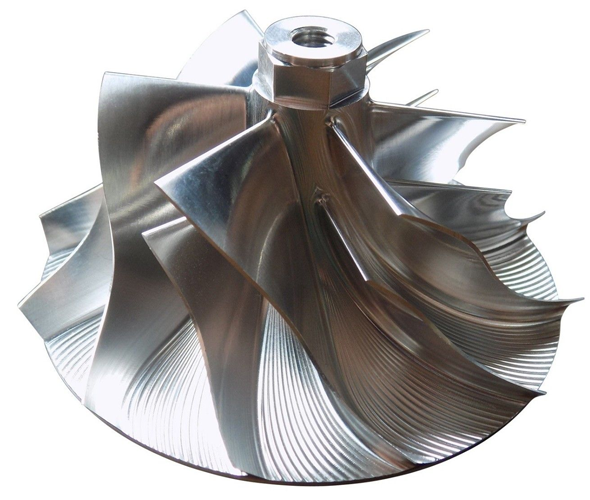

Axial Flow Impeller

Due to the large blade angle, machining must ensure a smooth surface to enhance fluid dynamic performance, reduce resistance, and improve overall efficiency.

Kesu’s strengths

A titanium alloy impeller is a high-performance rotating component used in pumps, compressors, and turbines. It is designed to move fluids or gases efficiently while withstanding extreme conditions. Titanium alloys, such as Ti-6Al-4V, are commonly used due to their high strength, corrosion resistance, and low weight.

Common Applications: Aerospace, automotive, construction, electronics

An aluminum alloy impeller is a lightweight, high-performance rotating component used in pumps, fans, compressors, and turbines to move fluids or gases efficiently. Made from aluminum alloys like 6061, 7075, or A356, these impellers provide a balance of strength, corrosion resistance, and cost-effectiveness.

Common Applications: Aerospace, medical implants, marine applications

A nickel-based alloy impeller is a high-performance rotating component used in extreme environments requiring exceptional corrosion resistance, high-temperature strength, and durability. Common alloys include Inconel, Hastelloy, and Monel, which provide superior mechanical properties for demanding applications.

Common Applications: Aerospace, medical implants, marine applications

A steel alloy impeller is a robust rotating component used in pumps, turbines, and compressors, designed for high strength, durability, and wear resistance. Common steel alloys include stainless steel (304, 316, 410), duplex stainless steel, and high-strength carbon steels.

Common Applications: Aerospace, medical implants, marine applications

Why Choose Kesu for Impeller Machining?

Quality Assurance

Kesu employ rigorous quality control measures throughout the milling process, ensuring that each part meets or exceeds your expectations. Advanced inspection equipment further guarantees accuracy.

Competitive Pricing

Without sacrificing quality, Kesu offers competitive pricing for our custom services. We strive to provide cost-effective solutions, making advanced manufacturing accessible to businesses of all sizes.

Exceptional Customer Service

Kesu‘s dedicated customer support team is always ready to assist. From initial inquiries to project completion, we maintain open communication, ensuring a seamless and satisfying experience.