Within the context of the intelligent and high-end revolution of the manufacturing industry, problems in the production of multi-specification impellers have become even more pronounced. These crucial pieces of equipment are widely utilized in energy devices, aero-engines, gas turbines, as well as in high-speed chemical pumps. They are typified by complex structures, large geometric nonlinearity, and the use of hard-to-machining metals (such as titanium alloy and nickel-based alloys), with incredibly stringent manufacturing accuracy and homogeneity requirements. Classical manufacturing modes, however, struggle to keep up with the requirements of diversiform types, small lots, and rapid delivery.

Introduction

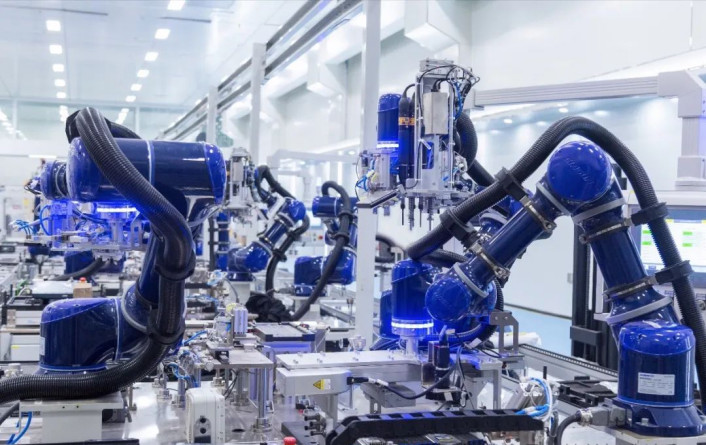

Industrial machine tools, or so-called “machines that make machines,” are not only processing equipment but have also turned into functional, platform-based, and fundamental basic modules in intelligent manufacturing systems. To integrate organically, schedule intelligently, and control systematically different industrial machine tools to achieve flexible response and high-quality production of multi-specification impellers is a key issue for manufacturing companies towards smart factories. Cooperative control and intelligent integration of industrial machine tools are, in my view, key foundations for the transition of the production of multi-specification impeller from “equipment-driven” to “data-driven.”

Analysis of Challenges in Multi-Specification Impeller Production

Multi-specification impeller products, under the contemporary high-end manufacturing environment, increasingly served as a core product in aerospace, energy, and fluid equipment industries. Multi-specification impeller products, though not like single standard products, bring unprecedented challenges to the flexibility of processing systems, efficiency of resource coordination, and precision of quality control. In this article, it systematically analyzes its main challenges from four typical aspects, hoping to provide a technical basis for the application of subsequent intelligent solutions.

Highly Heterogeneous Product Structures

Multi-specification impellers are highly disparate in diameter size range (50 mm–1200 mm), number of blades (6–36), curvature of channels, and inlet/outlet angles, resulting in highly nonlinear and locally complicated geometric forms. In CAM programming, traditional template-based path design models are hardly in a position to support such highly customized forms, with more powerful geometric perception algorithms and multi-axis interpolation optimization mechanisms required. Meanwhile, the allowance distribution, cutting depth-width ratio, and tool interference space are uneven in different impellers, which further confirms the requirement of “point-to-point response capability” of process paths. In other words, while processing highly heterogeneous impeller geometries, the processing system not only “can process” but also “process accurately, efficiently, and adaptively.”

Frequent Tooling Changeovers

Multi-specification impellers are typically in batches or trial runs, and frequent changes of several product models make traditional fixed tooling inefficient. Manual disassembly, repositioning, leveling, and test cutting verification is labor and time intensive in traditional fixture replacement. New positioning errors might be introduced with each changeover, significantly affecting the stability of processing. Changing 3–5 models of impellers per day is a common phenomenon in some common projects. If mechanical changeover of fixtures and manual clamping are continued to be used, production efficiency will decrease significantly, and controlling the beat of flexible manufacturing will be challenging. Therefore, integrating modular quick-change tooling, zero-point positioning systems, and changeover presets from fixture databases is now a necessary path to achieve efficient changeover and manageable error.

High Pressure for Precision Consistency

Despite product specification heterogeneity, customer demands for geometric consistency and performance stability of each batch of impellers have not waned. Most notably in high-reliability sectors such as aerospace, each one-piece error can affect the assembly or aerodynamic efficiency of the entire machine. In multi-specification manufacturing, due to changes in equipment status, differences in operator experience, and ongoing process path updating, the “first piece qualified, batch drift” effect will surely occur. More importantly, the path for error chain transmission is complex, with tool wear, clamping deformation, thermal drift, and program misconfiguration interacting to make control difficult. For example, during the five-axis machining of a batch of titanium alloy impellers, failure to reset the tool setting point during changeover meant all 5 completed products in the batch had a thickness error of ±0.03 mm, outside the design tolerance range. It can be seen that consistency control is not solely reliant upon precision equipment but also process-based systems and full-process error closed-loop control measures.

Information Silos and System Integration Difficulties

Design models, processing technologies, program files, tool parameters, and inspection data relating to multi-specification impellers are scattered across multiple autonomous systems (e.g., CAD systems, CAM platforms, CNC controllers, MES systems, and quality management platforms). Poor data exchange and the absence of version unification have become core bottlenecks constraining manufacturing collaboration effectiveness. Especially in cases where products are frequently replaced, unless there exists a means of automatic correlation between systems, upload errors in programs, misuse of older version models, or loss of parameters will likely occur, leading to chain rework and delays in deliveries. I have once conducted a process diagnosis of a manufacturing hub and found that the “program import and version verification” linkage alone took on average 1.5 hours a day, which translated into up to 25% of the total changeover time. It is therefore important to build a consistent data and make digitalization of process knowledge and modeling of manufacturing resources key to breaking down information silos and optimizing system integration.

Collaborative Roles and Typical Applications of Industrial Machine Tools

Under the condition of multi-specification aerospace impeller production experience, the processing capacity of a single tool can hardly meet the current demands of high precision, high efficiency, and multi-varieties mixed-line production. Especially in the context of challenges of process bottlenecks, quick changeover, traceability of quality, and manufacturing stability, industrial machine tools are no longer simply “processing tools” but become the core component of an intelligent manufacturing system, with the need to play a more profound systematic role in equipment collaboration, process coupling, and intelligent scheduling. Diversifying some production conditions, this article sums up the co-positional working and technical merit of four general industrial machine tool units in the production of impellers.

(1) Five-Axis Machining Centers — The Core of Complex Geometry Processing

Five-axis machining centers, with their enhanced spatial freedom and path continuity, have been the mainstay in the production of impeller-type components. The internal structure of impellers mainly consists of spiral grooves and free surfaces, and processing difficulties are concentrated at blades-disc junctions. Traditional three-axis or four-axis strategies are prone to interference, back-cutting, and residue materials, unable to ensure the uniformity of surfaces and tool safety. Through real-time control of the tool axis attitude, five-axis machine tools can sustain continuously the optimal contact angle among the workpiece and tool tip, practically eliminating the possibility of reverse cutting interference. In a 460mm titanium alloy impeller production project, I verified that high-rigidity five-axis gantry machining centers such as the Makino D500 with high-dynamic path control parameters are capable of effectively inhibiting tool vibration and detail jumping when machining micro-surfaces using long-overhang ball-end tools so the precision consistency of blade root to tip is ensured at ±0.01 mm. In addition to this, path pre-reading and interference analysis modules provided by five-axis CAM systems such as UG NX and HyperMill can perform online self-adjustment and predictive optimization of tool paths, further enhancing the stability and flexibility of the processing process.

(2) Turn-Mill Composites — A Powerful Tool for Integrated Structure Processing

For shaft-like or flange assembly structures of impeller parts, conventional methods must undergo numerous alterations between turning, milling, drilling, etc., with frequent fixture and machine changing, which results in low efficiency and tremendous accumulated precision errors. Turn-mill integrated machines (e.g., Mazak INTEGREX and DMG MORI NT series) can complete multi-process integrated processing from rough turning of outer circle, finish machining of end face to precision milling of channels in a single clamping, reducing greatly the transfer time and human clamping errors. For example, in machining a multi-stage impeller configuration with twin-shaft seal interfaces, turn-mill composite technology reduced the processes that would otherwise occupy three machines to clamping in just one machine, shortening the processing cycle from 22 hours to 12 hours and improving precision retention by up to 30%. The structural integration capability makes it the most popular platform for the machining of complex-structured impellers, especially modular pump wheels with mounting bases.

(3) Automatic Fixture Systems — The Core Base for Rapid Changeover

High rate replacement of workpieces is a primary obstacle to restrict productivity and adaptable reaction in the event of mixed-line manufacturing of multi-model impellers. Manual assembly and disassembly of fixtures are time-consuming and labor-intensive, involving large repeat positioning inaccuracies. Automatic fixture systems, with the coming of modular rapid-change tooling and zero-point positioning systems (e.g., Erowa, Lang, or Schunk zero-point systems), can have full automatic fixture exchange and workpiece location in 5 minutes, with repeat positioning precision controlled to ±0.005 mm, greatly improving on-site changeover efficiency and processing consistency. In a multi-series gas pump impeller project, use of this system improved the changeover efficiency more than 3 times and reduced changeover precision deviation fluctuations to 40% of the original one, thereby allowing for flexible production requirements of small batches and diverse varieties.

(4) On-Machine Measurement and CMM Inspection — The Core of Quality Control Closed-Loop

Impeller products have complex geometric structures, with free-form parametric surfaces. Traditional offline inspection methods have the drawbacks of sparsely distributed points of measurement, long cycles of inspection, and late rework notification. On-machine metrology systems (e.g., Renishaw RMP600), set on five-axis machine centers, enable direct inspection following tool processing and on-line comparison of measurement information against processing paths, using a quality closed-loop procedure of “correcting while processing.” During the final-stage inspection, high-accuracy coordinate measuring instruments (e.g., ZEISS Prismo and Hexagon Leitz) and specialty impeller fixtures are able to conduct full-domain scanning on the entire impeller channel surface, wall thickness, and profile, producing heat maps and trend traces of errors at critical positions. Combined with the data feedback capability of MES systems, measurement data can be automatically saved into a quality tracking database, making traceability of production data possible and performing root cause analysis of quality issues, thereby fully promoting the initiative of quality management and system response speed.

Production Line Collaborative Control System Design: A Systems Engineering for Flexible Manufacturing

The success of successful flexible manufacturing must rely on the profound integration of a number of system modules. From my actual practice in production line reconstruction, the systematic cooperation of the following connections guarantees flexibility:

| Collaborative Module | Function Description |

| Process Planning Platform | Build process templates for multi-specification impellers, automatically generate processing paths and tool strategies |

| CNC System Integration | Unify NC programs, tool compensation, and equipment interfaces to improve multi-machine collaboration efficiency |

| Automated Logistics System | AGV + rack systems complete efficient transfer of different types of impellers between machine tools |

| MES Platform | Realize real-time scheduling and visualization of process, planning, equipment, and quality data |

Through these combined designs, not just the efficiency of production is significantly improved but also the scalability and fast iteration capability of the production line are attained.

Conclusion

Flexible production of multi-specification impellers is a benchmark for high-end equipment manufacturers in their upgrading to intelligent manufacturing. With an industrial machine tool-oriented system integration and collaborative manufacturing system, enterprises not only can deal more effectively with the complexities of complex structures of impellers, small batch sizes, and high precision but also establish future production lines with quick response capability, high-quality guarantee capability, and continuous innovation capability.