Custom Online CNC Machining Services

Looking for reliable manufacturers who deliver quality parts at competitive prices? Kesu offers comprehensive online CNC machining services through a single trusted source. Our platform connects you with a wide range of manufacturing solutions to meet your production needs efficiently and cost-effectively.

Start A New CNC Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

Why Use Kesu for Custom Online CNC Machining Services?

Kesu is the ideal choice for custom CNC machining, offering unparalleled convenience and quality. Our vast network of over 10,000 vetted suppliers, including AS9100D certified shops, ensures top-tier manufacturing for any design, simple or complex. Kesu simplifies procurement, providing instant quotes, lead times, and DFM feedback through our online platform. We handle everything from rapid prototyping to high-volume production, expertly managing your order from start to finish. Benefit from our materials expertise, competitive pricing, and commitment to delivering high-quality metal and plastic parts, all while enjoying the support of experienced engineers.

At Kesu, we prioritize flexibility and excellence in our services. With no minimum order requirements, we accommodate projects of any size. Our commitment to consistency and quality is reflected in our thorough analysis process, where we carefully determine crucial parameters like parting lines and gate locations after order confirmation. Thanks to our advanced manufacturing capabilities, we maintain short delivery times without compromising quality. Our state-of-the-art production facilities ensure precise execution of every project, delivering superior results that meet your exact specifications.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process that uses computerized controls and precision tools to shape workpieces by removing material. Widely applied in aerospace, automotive, electronics, and medical industries, it operates through machines like milling machines, lathes, routers, and grinders. Using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, designs are translated into precise programming instructions executed by the CNC machine, enabling the production of complex parts from materials such as metals, plastics, and ceramics.

CNC machining offers high precision, tight tolerances, and exceptional repeatability, ensuring consistent quality. Its efficiency stems from reduced manual intervention and its versatility in handling various materials and geometries. Ideal for both mass production and customized small batches, CNC machining has become a cornerstone of modern manufacturing. By producing intricate and durable parts, it supports innovation and technological advancements across multiple industries.

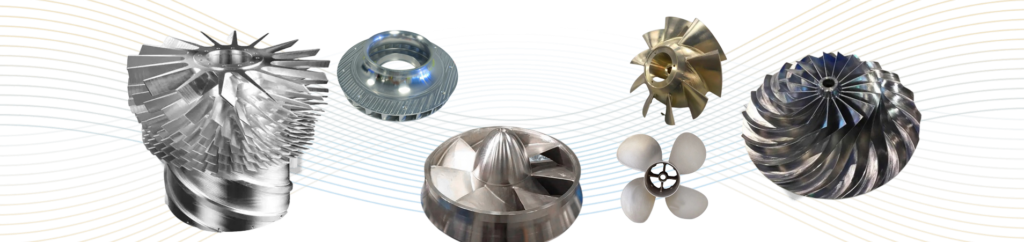

Custom CNC Machining Services: Turning, Milling, Routing,3D Printing And Injection Molding

Custom CNC Milling Services

Our facility features 32 advanced 5-axis CNC milling machines, enabling us to manufacture complex plastic and metal components with precise tolerances. Additionally, our 3- and 4-axis milling equipment provides efficient and economical production solutions to meet your specific needs.

CNC Turning Service

Our CNC turning capabilities excel at producing cylindrical parts from plastic or metal stock materials, such as worm shafts, with maximum efficiency. Combined with live tooling technology, we can simultaneously perform milling operations, enhancing production versatility and reducing manufacturing time.

3D Printing Service

Kesu provides professional 3D printing services with multiple material options, ensuring high precision, complex structure printing, and fast delivery. Widely used in automotive, medical, electronics, and aerospace industries.

Injection Molding Services

Kesu provides high-precision, cost-effective injection molding solutions for small-batch and large-scale production, serving industries like automotive, medical, and electronics. Get a quote today to start your project!

CNC Machining Tolerances

Feature |

Description |

|---|---|

Part Size Capacity | Milling: Up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

Standard Lead Time | As fast as 3 business days. |

General Tolerances | Metals: +/- 0.005" (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. |

Precision Tolerances | Capable of achieving tolerances tighter than +/- 0.001" (+/-0.025mm), including more stringent requirements. |

Minimum Feature Size | Down to 0.020” (0.50 mm). |

Threads and Tapped Holes | All standard thread sizes accommodated. |

Edge Condition | Sharp edges are broken and deburred by default for safety and improved part handling. |

Surface Finish | Standard: As-machined finish of 125 Ra or better. |

We are able to offer a precision machining service with a wide array of tolerances. The table below depicts the general tolerances for CNC machining:

Metal CNC Machining Materials.

Aluminum 6061

6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075

7075-T6

Aluminum ADC12 (A380)

Copper C101(T2) Copper C103(T1) Copper C103(TU2) Copper C110(TU0) Beryllium Copper |

Bronze, an alloy of copper and tin, is known for its durability and resistance to corrosion. It’s widely used in marine applications, sculptures, and bearings, thanks to its strength and ability to withstand harsh environments.

Stainless Steel SUS201

SUS303

SUS 304

SUS316

SUS316L

SUS42

SUS430

SUS431

SUS440C

SUS630/17-4PH

AISI 304

Steel 1018 Steel 1020 Steel 1025 Steel 1045 Steel 1215 Steel 4130 Steel 4140 Steel 4340 Steel 5140 Steel A36 Die steel Alloy steel Chisel tool steel Spring steel High speed steel Cold rolled steel Bearing steel SPCC |

Titanium Alloy TA1、 Alloy TA2 Alloy TC4/Ti-6Al 4V |

Plastic CNC Machining Materials

ABS Beige(Natural) ABS Blac ABS Blac Antistati ABS Milky Whit ABS+PC Black ABS+PC White |

PC Black PC Transparent PC White PC Yellowish White PC+GF30 Black |

PMMA Black PMMA Transparent PMMA White |

PA(Nylon) Blue PA6 (Nylon)+GF15 Black PA6 (Nylon)+GF30 Black PA66 (Nylon) Beige(Natural) PA66 (Nylon) Black |

Dark brown (coffee) POM 100AF POM Black POM Blue POM White |

HDPE UHMW-PE LDPE |

PEEK Beige(Natural) PEEK Black |

CNC Machining Design Guidelines

Feature |

Description |

|---|---|

Internal Corner Fillets | For internal corner fillets, design radii to be 0.020” - 0.050” larger than the standard drill size. Follow a drill diameter to depth ratio of 1:6 (preferably 1:4) to ensure proper clearance and tool accessibility. This helps prevent tool wear and improves machining accuracy in tight corners. |

Floor Fillets | Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior. This helps avoid tool interference and improves machining efficiency. Ensure the floor radius is proportionate to the part’s thickness to maintain structural integrity. |

Undercuts | When designing undercuts, ensure they follow standard sizes and are positioned away from corners for better tool access. Avoid overly intricate undercut designs, as they can complicate tooling and increase machining time and cost. |

Tapped/Threaded Hole Depth | Ensure the depth of tapped or threaded holes provides enough clearance beyond the threads for the tool to fully form the threads. The hole depth should account for tool length and material properties to prevent incomplete threads or part damage. |

Complexity | Minimize the number of intricate or small cuts in your design to reduce CNC machining costs. Focus on including only essential features that balance functionality with aesthetics. A simplified design approach can improve manufacturing efficiency and reduce overall costs. |

Start Your CNC Machining Project

CNC Machining FAQs

Computer Numerical Control (CNC) machining is a method used in the making of high-precision parts using automated means. It uses computer software for controlling machine tools such as mills, lathes, and routers. The process begins with the design of a part using CAD, or Computer-Aided Design software, followed by converting the design into machine-readable instructions (G-code) using CAM or Computer-Aided Manufacturing software.

These instructions are followed by the CNC machine in order to precisely cut and shape raw material into the desired part. The process is highly automated, allowing for greater accuracy, repeatability, and efficiency compared to traditional manual machining. After the machining of the part, it undergoes an inspection to ensure that the quality meets the required specifications.

The main differences between CNC machining and traditional machining are the degrees of automation, precision, and production efficiency. In CNC machining, there is a high level of automation through the use of computer-controlled machines that perform in accordance with specific instructions guided by CAD designs. Once programmed, these machines can run continuously with minimal human intervention, offering consistent and precise results. This is a great process for complex parts that have tight tolerances in geometry; thus, this process can be targeted for industries like aerospace, medical, and automotive. Additionally, CNC machining provides for faster production time and minimizes the chances of human error.

Traditional machining, on the other hand, is based on operation by hand, where a machinist directly controls the machine tools. Such operators will change the settings and make the cuts by hand, something that requires a lot of experience and skill. Traditional machining, while it may be effective with less complicated parts, has processes that are generally more time-consuming and less effective in high-volume production. Traditional machining also depends greatly on the machinist's expertise; hence, maintaining consistency from one part to another can become very difficult.

While there are those differences, traditional machining has advantages in some cases. It tends to be less expensive when it comes to equipment and set-up costs and is ideal for either small production runs or less intricate designs. For complex parts or high-volume production, though, CNC machining definitely has superior speed, accuracy, and efficiency.

CNC machining is widely used in industries where precision, efficiency, and high-quality production are essential. In the aerospace industry, CNC machining is critical for producing complex parts like engine components, landing gear, and structural parts, where tight tolerances are crucial for safety and performance. Similarly, the automotive sector relies on CNC for manufacturing engine components, transmission parts, and custom pieces for performance vehicles, ensuring high precision in high-volume production.

In the medical field, CNC machining is used to produce surgical tools, implants, and prosthetics, where accuracy and reliability are paramount. The electronics industry benefits from CNC technology for crafting components such as connectors, heat sinks, and enclosures for electronic devices, ensuring consistent quality. These industries, along with many others, rely on CNC machining for its ability to produce intricate designs with high repeatability, reducing human error and enhancing production efficiency.

The history of CNC (Computer Numerical Control) machining dates back to the late 1940s and early 1950s, when the concept of automated machine tools began to take shape. Before the development of CNC, machines were operated manually by skilled machinists. In the 1940s, the U.S. Air Force collaborated with MIT to create a system that could automate the control of machine tools. The result was the development of numerical control (NC), where machines were controlled by punched paper tapes containing instructions for the tools. This innovation was mainly used for military applications, particularly for making parts for aircraft and defense systems.

In the 1960s, CNC machining emerged as a major advancement. With the introduction of computer-based control systems, CNC machines could now receive instructions from digital files instead of paper tapes. This allowed for greater precision, flexibility, and repeatability in machining operations. By the 1970s, CNC machines became widely used in industries like aerospace, automotive, and manufacturing. As computing power improved, CNC machines became more sophisticated, with capabilities for complex and intricate designs. Today, CNC machining is a cornerstone of modern manufacturing, used in a wide range of industries to produce high-precision parts and components.

Inspection in CNC machining is vital to ensure that machined parts meet design specifications and maintain high-quality standards. A common method is visual inspection, where surface defects and irregularities are checked manually. For more detailed checks, tools like calipers, micrometers, and height gauges are used for dimensional inspection, offering cost-effective solutions for simple measurements. These tools ensure that basic tolerances are met but may not suffice for complex components.

For advanced requirements, Coordinate Measuring Machines (CMMs) and optical inspection systems are utilized. CMMs use probes to verify precise dimensions, while optical systems capture intricate details with cameras and lenses. Additionally, surface finish testing with profilometers ensures the part meets roughness specifications, while functional testing assesses performance under simulated conditions. Combining these methods provides a comprehensive approach, ensuring accuracy and reliability for industries like aerospace, medical, and automotive, where tight tolerances and consistent quality are critical.

Tolerances for machined parts define the acceptable variation in dimensions to ensure proper functionality and fit. These tolerances depend on the machining process, material, and application. Typically, standard CNC machining tolerances are ±0.005 inches (±0.13 mm) for metals and ±0.010 inches (±0.25 mm) for plastics, but tighter tolerances can be achieved with advanced techniques and tools.

For critical features, tolerances can range as low as ±0.001 inches (±0.025 mm), especially in industries like aerospace, medical, and electronics, where precision is vital. Factors like tool wear, machine calibration, and material stability impact tolerance capabilities. Additionally, tighter tolerances may increase costs due to additional machining time and inspection requirements.

Yes,Kesu provides fast lead times for quick-turn parts, with many available in just 3-4 days. We also offer an expedited service, and our team collaborates closely with you to ensure your most urgent deadlines are met.

Why Choose Kesu?

Quality Assurance

Kesu employ rigorous quality control measures throughout the milling process, ensuring that each part meets or exceeds your expectations. Advanced inspection equipment further guarantees accuracy.

Competitive Pricing

Without sacrificing quality, Kesu offers competitive pricing for our custom services. We strive to provide cost-effective solutions, making advanced manufacturing accessible to businesses of all sizes.

Exceptional Customer Service

Kesu‘s dedicated customer support team is always ready to assist. From initial inquiries to project completion, we maintain open communication, ensuring a seamless and satisfying experience.