Blogs

All our latest ideas and events on impeller rapid prototype manufacturing.

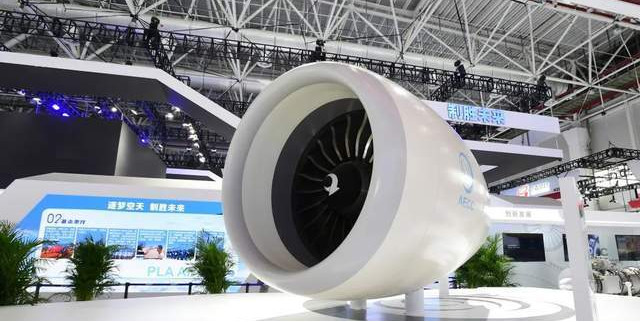

Practice on Construction of On-Time Delivery Assurance System for Aero-Engine Impellers

Being a high-integration, high-reliability, high-precision power system, the central component of the aero-engine—impeller—does not only carry out the central process of energy conversion but also its process quality and

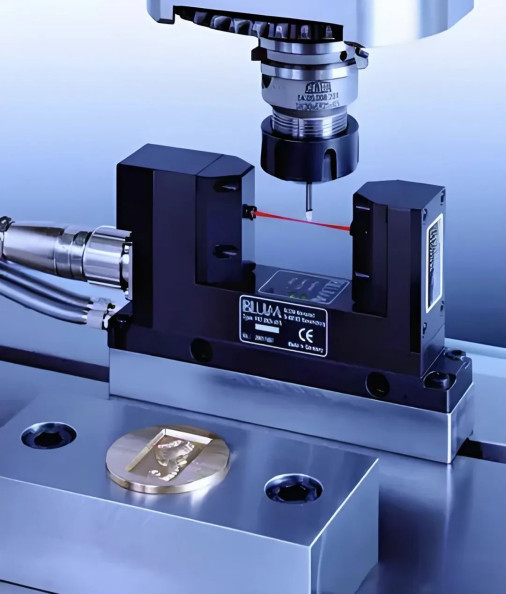

Integrated Design of Automatic Tool Setter for On-Line Detection in CNC Impeller Machining

With precision machining demanded by high-end manufacturing, especially the aerospace and energy sectors, on a larger scale, traditional manual tool setting processes are increasingly reflecting bottlenecks in

Evaluation of Application Advantages of High-Speed Machining Centers in Aviation Titanium Alloy Impellers

Titanium alloy impellers are widely used in aero-engine compressors and turbine equipment as the central components responsible for high performance and reliability in aviation power

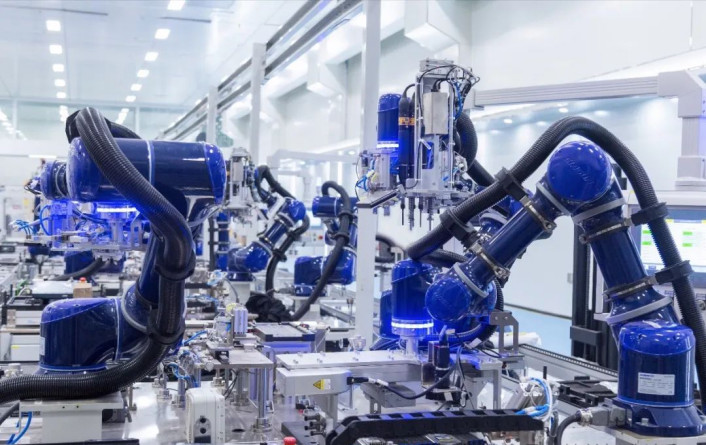

Collaborative Application of Industrial Machine Tools in Flexible Production of Multi-Specification Impellers

Within the context of the intelligent and high-end revolution of the manufacturing industry, problems in the production of multi-specification impellers have become even more pronounced. These crucial pieces of

Analysis of Efficiency Improvement of High-Pressure Cooling Systems in High-Speed Cutting of Nickel-Based Impellers

Nickel-based alloys have wide usage in crucial parts such as aero-engine compressor impellers due to their excellent high-temperature strength, oxidation resistance, thermal fatigue characteristics. Despite

Vibration Testing and Dynamic Response Analysis of Aero-Engine Impellers

Aero-engine impellers operate for a long time with severe conditions such as high rotation speed, high temperature and pressure, and strong aerodynamic excitation. Their dynamic response characteristics

Synchronous Control Technology of Multi-Axis CNC Systems in Complex Impeller Machining

As high-performance impellers are in demand in the manufacturing industry, the structure of impellers is also becoming more complex, and demands on CNC systems to machine them are greater. Three-

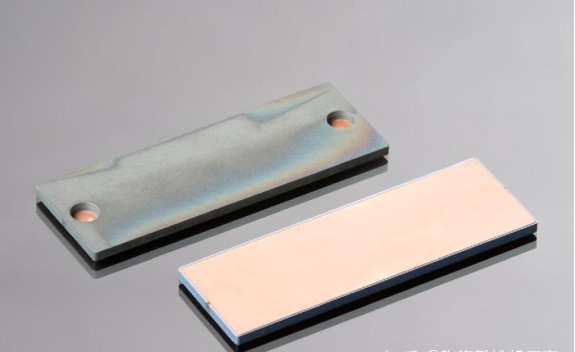

Surface Passivation Treatment and Salt Spray Test Analysis of Corrosion-Resistant Alloy Impellers

Corrosion-resistant alloy impellers are widely used in corrosive environments such as chemical processes, seawater pipelines, sewage treatment facilities, and high-salt and humid environments. They

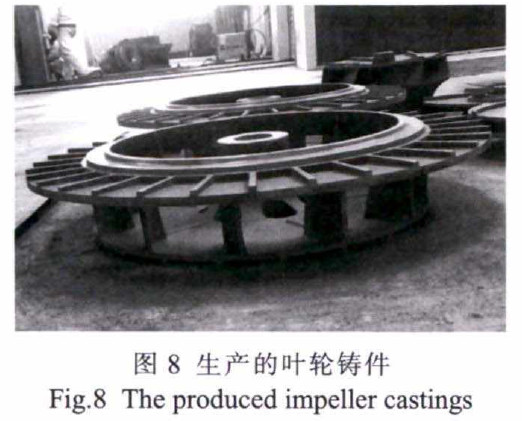

Effect of Heat Treatment Regimes on Microstructure and Properties of Nickel-Based Alloy Impeller Castings

Nickel-based alloys, owing to their excellent high-temperature strength, creep strength, and acceptable corrosion resistance, have become the preferred material for hot-end components such as aero-engines and high-

Application Practice of Industrial-Grade 3D Printing in Small-Batch Customized Impeller Manufacturing

Being a key part of centrifugal compressors, liquid pumps, and other fluid machinery, impellers directly affect gas dynamic performance and also have effects on the efficiency, vibration characteristics, and service life of the

Precision Cleaning of Aerospace-Grade Impellers and Process Optimization for Ultrasonic Decontamination

Turbopump impellers and compressor impellers, key elements in spacecraft propulsion systems, are typically manufactured from materials including titanium alloys, superalloys, or high-strength aluminum alloys.

Practice of Full-Process Digital Management and Control for Impeller Manufacturing Based on MES System

With the rapid development of intelligent manufacturing, production management of high-precision parts such as impellers must also urgently be converted to digitization to improve the efficiency of production, quality of

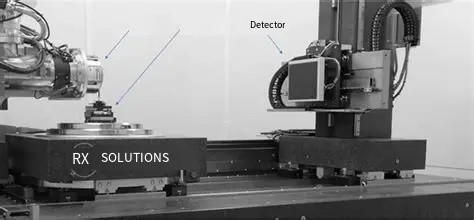

Application Research of Industrial CT in Defect Detection of Complex Internal Cavity Impellers

Complex internal cavity impellers are widely used in aero-engines, gas turbines, and high-pressure pump devices. Their internal configuration mainly comprises closed curved surfaces, thin flow passages, and three-dimensional

Analysis of Wear Mechanisms for Silicon Carbide Reinforced Aluminum Matrix Composite Impellers

SiC/Al composites possess excellent application prospects in light high-performance components such as high-speed rotating impellers due to their excellent specific strength, wear resistance, and thermal stability.

Airtightness Testing Process Standard Formulation for High-Altitude Application Impellers

Working at high altitude, the low pressure, thin air, and large temperature difference add greater requirements for the airtightness of key components of power equipment.

The Role of High-Precision Coordinate Measuring Machine in Impeller Tooth Profile Accuracy Control

As a crucial component of fluid machinery, the tooth profile accuracy of an impeller will directly affect the aerodynamic performance, energy efficiency, and operating stability of equipment. As the structural complexity

Process Advantages of Multi-Axis Linkage Equipment in Machining Bidirectional Curved Impellers

Bidirectional curved impellers are widely used in high-performance fluid machinery such as aero-engines, gas turbines, and special compressors. Their geometrical shapes are complex, with blades usually displaying both

Improvement of Finishing Processing Technology for Resin Sand Cast Impellers

Resin sand casting is widely used in the manufacturing of medium and large impeller blanks because it has high forming precision and high adaptability to complex structures. Directly cast impellers