Complex internal cavity impellers are widely used in aero-engines, gas turbines, and high-pressure pump devices. Their internal configuration mainly comprises closed curved surfaces, thin flow passages, and three-dimensional variable cross-sections, which are difficult for traditional non-destructive testing methods to perform complete internal defect detection. Industrial Computed Tomography (Industrial CT) has been recognized as an effective method for complex internal cavity impeller defect inspection due to its non-contact, high-precision, and full 3D imaging properties.

Introduction

With increasing requirements for impeller performance in aeronautical and high-performance energy equipment, complex internal cavity impellers have emerged as ever more important engineering products, especially in high-temperature and high-pressure applications such as aero-engines and gas turbines where structural intricacy and manufacturing accuracy are subject to stricter demands. Especially after the promotion of advanced manufacturing techniques such as 3D printing and precision casting, impellers normally possess internal defects such as pores, inclusions, and fusion defects that can affect the performance and safety of impellers. Therefore, the question of how to inspect the defects of complex internal cavity impellers efficiently and accurately has become an earnest problem to be solved.

Traditional non-destructive testing methods, such as ultrasonic, eddy current, and X-ray radiography, cannot meet the demand of high-precision detection due to a lack of detection resolution or blind detection regions in the complicated shape of impellers. As a non-contact X-ray-based imaging technology, industrial CT can provide high-resolution 3D imaging for defect detection of complicated internal cavity impellers. In this article, the application of industrial CT in the detection of complex internal cavity impeller defects, its advantages and disadvantages, and corresponding solutions will be described.

Structure and Detection Difficulties of Complex Internal Cavity Impellers

Complex internal cavity impellers usually have the following major characteristics:

Complex Flow Channel Structure

The inner space of the impeller exhibits different structures such as spiral, curved, and variable cross-sections. General detecting devices are not in a position to touch the inner surface well, limiting the application of common detecting techniques.

Closed or Semi-Closed Spaces

Most of the internal cavities of impellers are closed or semi-closed, and it is difficult for general flaw detection methods such as ultrasonic and eddy current to penetrate in directly and obtain effective signals, resulting in large blind zones in detection results.

Diverse Material Types

Impellers are normally made from materials such as titanium alloys, nickel alloys, and aluminum alloys. The materials have largely different X-ray absorption characteristics, and traditional radiography processes tend to be prone to creating artifacts and affecting the detection of defects.

Diverse and Difficult-to-Identify Defect Types

Common defects such as pores, inclusions, cracks, and lack of fusion are of micron size and in deep interior cavity of the impeller, which is out of reach for using conventional methods to detect these defects effectively and accurately.

Industrial CT, with its 3D imaging and non-contact advantages, is capable of precise defect detection and breaking the limitations of conventional means of detection, especially exhibiting great potential to detect intricate internal cavity impellers.

Detection Principle and Process of Industrial CT

With the development of advanced manufacturing technologies, complex structural components such as impellers bring greater demands for the accuracy and visualization of non-destructive testing. Compared with traditional detection methods such as ultrasonic and single-sided X-ray fluoroscopy, Industrial Computed Tomography (Industrial CT) has become a main tool for internal defect detection and structural testing of high-quality impellers due to its capability of 3D imaging and sub-micron resolution. For the sake of better explanation of its application mechanism, the following explains the principle of detection and application process of industrial CT in a logical sequence.

Principle Introduction

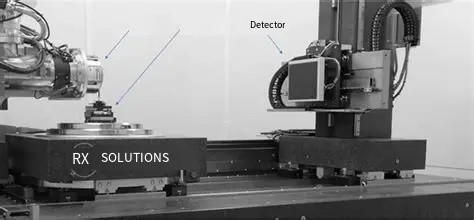

Industrial CT is based on the principle of X-ray transmission imaging. It scans X-rays onto the impeller sample in various directions and detects the ray signals that were attenuated using a detector to obtain the attenuation images of each slice. Areas with varying materials and densities absorb X-rays differently, thus materials with varying characteristics and potential defects in the impeller can be distinguished by variations in gray levels in the images. Then, through image reconstruction algorithms such as the Filtered Back Projection (FBP) algorithm, two-dimensional images of the slices are reconstructed into three-dimensional data for defect detection and analysis.

Detection Process

- Sample Pretreatment: Remove oil and impurities from the impeller surface for clear scan images.

- Scan Parameter Setting: Choose suitable scan parameters like tube voltage, current, resolution (e.g., 5–50 μm), and exposure time based on the material and structural properties of the impeller.

- Data Acquisition: Scan 360° using a high-resolution detector to acquire attenuation images at various angles.

- Image Reconstruction: Implement FBP or other reconstruction methods to transform original two-dimensional images into three-dimensional data, reconstructing a complete internal structure.

- Defect Identification and Analysis: Utilize image analysis and processing software to identify and quantitatively examine defects such as pores, cracks, and inclusions, and generate reports on defect distribution.

Application Analysis of Industrial CT in Typical Defect Detection

As the technology for impeller manufacturing develops into high precision and high complexity, the constraints of traditional flaw detection technology in detecting internal defects become increasingly evident. Most especially when it comes to cast, additive manufactured, or complex multi-material structure impellers, how high-resolution and non-destructive detection of very small defects can be guaranteed has been a pressing issue in product reliability and quality control. Industrial Computed Tomography (Industrial CT) with its 3D high-resolution imaging function has become one of the major tools in detecting typical internal flaws of impellers. The following analyzes its individual application performance in the detection of defects from four aspects.

Detection of Porosity and Shrinkage

When casted with an impeller or laser additive manufacturing, volumetric defects such as porosity and shrinkage are dễ (likely to) occur. The minute voids are often_deeply buried (deeply concealed) in the material, and the ordinary X-rays difficualt (hard to) accurately locate them. Industrial CT can truly represent the three-dimensional density distribution of the workpiece in multi-angle ray reconstruction, naturally showing size, quantity, and distribution characteristics of pores. For example, under high resolution conditions, industrial CT can recognize closed pores with a size less than 1 microliter and perform accurate quantification depending on image segmentation technology. This not only helps in evaluating whether local density meets the requirement but also provides feedback to optimize the process parameter such that it avoids fatigue cracks or burst failure due to pore accumulation.

Identification of Lack of Fusion and Cracks

The main sources of risk resulting in structural weaknesses in welding repair and additive manufacturing processes are lack of fusion defects at interlayer. These imperfections usually occur as thin sheets extended out at material interfaces or corner positions. High gray-scale resolution industrial CT is capable of producing substantial contrast between different phases of materials or interfaces, and thus the lack of fusion area will have a clearly distinguishable “dark band” feature. In multi-dimensional channels of impellers, roots or through-holes, if micro-cracks exist, traditional flaw detection methods such as ultrasonic or surface coloring cannot identify them, but industrial CT can accurately offer parameters such as their shape, length, and depth, to facilitate subsequent reliability analysis and strength calculation.

Identification of Inclusions and Foreign Objects

If inclusions of raw material impurities, slag residues oxide inclusions, or foreign bodies are brought in during the manufacturing process of the impeller or during assembly and cleaning procedures, they will lead to serious effects such as stress concentration or local corrosion. Industrial CT can quickly identify inclusions with vastly differing densities from the matrix based on the disparity in X-ray absorption coefficients between materials and calculate their distribution locations in three-dimensional space with great accuracy. It is particularly good at finding alumina and carbide inclusions within titanium alloy or aluminum alloy matrices without the issues of premature failure due to foreign bodies.

Detection of Wall Thickness and Geometric Deviations

Industrial CT not only has the capability of defect recognition but also can convert the scan data into precision volume reconstruction models and model and match them with the original CAD model to accomplish macroscopic topography error visual inspection such as wall thickness variation, flow channel geometry displacement, and hole location deviation. By means of such an approach, the engineers can obtain important information such as the location of the thinnest wall, size distribution deviation map, and surface deviation trend, providing robust data support for future simulation analysis and assembly precision control. This “digital twin” quality detection function greatly improved the controllability of quality over the whole life cycle of the impeller.

Key Technical Difficulties and Solutions

Although industrial CT has shown impressive abilities in detecting complex internal cavity impellers, it still faces some technological limitations in actual applications, which mainly include inhomogeneous material X-ray absorption, resolution-conflict with scanning speed, large reconstruction calculation space, and difficult automated defect recognition. For solving these issues, the following technical measures have been proposed:

- Non-uniform X-ray Absorption by Materials: For high-density materials with large image noise and strong artifacts, dual-energy CT or multi-energy spectral imaging technology can be utilized to improve the image quality.

- Conflict Between Resolution and Scanning Speed: High resolution is equivalent to long exposure times, which will affect scanning efficiency. With this goal in mind, high-speed and high-resolution flat-panel detectors can be selected, and sampling algorithms can be optimized for better efficiency.

- Large Reconstruction Calculation Amount: Three-dimensional image data is large, and reconstruction speed is low. Through the use of GPU acceleration technology or cloud-distributed processing, calculation speed can be effectively enhanced and the detection cycle reduced.

- Difficulty in Automated Defect Identification: In order to improve accuracy and automation of defect identification, introducing an AI-aided identification system and training identification models for single defects can significantly enhance detection efficiency and accuracy.

Conclusion

Industrial CT technology has been proven to have good ability in the detection of intricate internal cavity impeller defects, especially with its outstanding superiority in high-precision localization and quantitative analysis. With continuous advances in technology, industrial CT will play a more leading role in the application in various links of impeller quality control in the future, providing safer and more efficient methods of detection for high-end impeller manufacturing. But problems still exist in material variety, the contradiction between resolution and scanning efficiency, and accuracy of automatic detection technology to be improved to further promote the wide application of this technology in actual production.