SiC/Al composites possess excellent application prospects in light high-performance components such as high-speed rotating impellers due to their excellent specific strength, wear resistance, and thermal stability. Although the material possesses improved mechanical properties and anti-wear performance, the material still suffers from various types of wear under complex working conditions such as particle debonding, micro-cutting, and fatigue spalling.

Introduction

As the demands for lightweight and high-efficiency power systems increase in aerospace, automobile, pump-valve, and other fields, silicon carbide reinforced aluminum matrix composites (SiC/Al) have increasingly become ideal materials for manufacturing high-performance impellers due to their excellent physical and mechanical properties. As a reinforcing phase, SiC has very high hardness, which can significantly enhance the wear resistance and thermal stability of aluminum matrix composites. This causes SiC/Al composites to possess excellent anti-wearability in high-speed rotating impellers with special superiority in particle erosion and variable working conditions.

But even if this material has theoretically better properties, actual applications still involve various complex wear modes like particle debonding, micro-cutting, impact crushing, etc. These wear forms exert significant effects on the service life and performance of impellers. Therefore, research on the wear mechanisms of SiC/Al impellers is of great significance to improve their wear resistance and extend their service life.

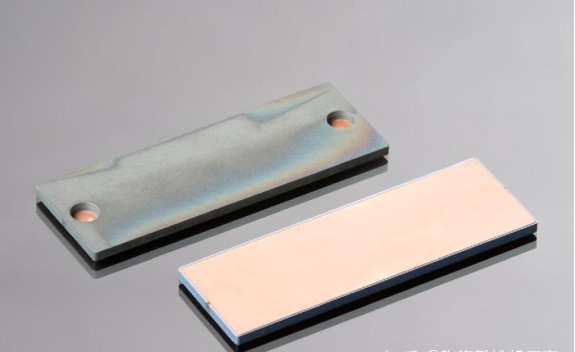

Structural Characteristics of Silicon Carbide Reinforced Aluminum Matrix Composites

SiC/Al composites are generally fabricated via processes such as powder metallurgy and stir casting, and their structural characteristics are mainly reflected in the following areas:

Distribution and Hardness of Reinforcing Phases

SiC particles have high hardness (HV > 2500) in general, and the distribution and uniformity of the particle size control the wear resistance of the material. The particle size is generally 5–20 μm, and the volume fraction is 10%–30%. Appropriate strengthening phases can be utilized to enhance the matrix rigidity and strength efficiently, but excessively high particle volume fraction will make the material brittle.

Role of Interfacial Bonding

Interfacial bonding between SiC particles and the aluminum matrix has an important influence on the mechanical behavior and wear performance of the composite. Too strong interfacial bonding may lead to particle breakage and stress concentration, and too weak interfacial bonding may lead to particle debonding, thereby facilitating wear.

Selection of Matrix Alloys

SiC/Al composites generally take heat-treatable Al-Si or Al-Cu alloy as the matrix, which have superior workability and toughness. The processability and mechanical properties of the composite are directly affected by the matrix alloy.

Typical Wear Forms of SiC/Al Impellers

SiC/Al composites are widely used to manufacture impellers for high-performance pumps, compressors, and supercharging systems due to their high specific strength, wear resistance, and thermal stability. However, under complex working conditions, especially in high-speed rotation, eroding media, and cyclic thermal loading environments, these impellers continue to suffer from a number of wear problems. Their service failures were analyzed and indicated that SiC/Al impellers mainly experience the following five typical wear mechanisms, each of which indicates material microstructure and service environment interaction.

Particle Debonding Wear

Particle debonding is one of the most common wear types of SiC/Al impellers, particularly evident in high-speed rotation or harsh airflow erosion conditions. When the composite is subjected to impact or shear loading, depending on the fact that the bonding force is inadequate or interfacial flaws exist between SiC particles and the aluminum matrix, the particles tend to peel from the matrix, thus resulting in microscopic pits. These pits not only directly increase the actual contact area but also act as sources of stress concentration in future service, leading to new particle debonding, forming a vicious cycle, and speeding up the overall wear process.

Micro-Cutting Wear

Under service conditions with hard particles (such as sand, iron oxide, silicon carbide debris, etc.), foreign particles have microscopic “plowing” cutting action on the impeller surface, forming narrow grooves and material loss areas. This kind of micro-cutting not only creates plastic deformation of the matrix material but can also destroy the stability of SiC particles embedded therein, causing secondary particle debonding. Surface roughening and local stress concentration usually follow micro-cutting wear, which has a great effect on the dynamic balance and aerodynamic performance of the impeller.

Fatigue Spalling Wear

During long-term service, impellers experience alternating stresses of rotational inertia, thermal cycles, and gas pulsations repeatedly, and there are repeated stress responses at the interface of SiC particles and matrix. Micro-cracks accumulate and propagate gradually at the interface and ultimately lead to local delamination of material, peeling of particles, or even spalling of flakes. This type of fatigue spalling usually occurs in the form of irregular shedding along the grain boundary direction on the surface, seriously damaging the aerodynamic shape of the impeller and being one of the main causes of premature failure.

Impact Crushing Wear

In high-speed particle impact application instances, i.e., solid impurity-containing fluid conveying systems, SiC particles on the impeller surface experience the strike of high-frequency impacts. During high-energy impacts, even high-hardness SiC particles can fracture or crush, and further cause stress concentration as well as erosion damage in the neighboring areas. Such wear is usually localized and sudden and often occurs first in high-load areas such as the leading edge of blades and blade roots.

Combined Corrosion-Wear Action

Under some service environments of seawater, acid-base solutions, or salt spray environments, the impeller material is not only under mechanical loading but also under the synergistic effect of chemical corrosion. The corrosion reaction lowers the interfacial bonding force, which promotes particles to be debonded easily. At the same time, the metal matrix suffers corrosion perforation and oxide layer spalling, resulting in a significant decrease in overall wear resistance. Tests show that the wear rate under the synergistic effect of corrosion and wear is 2–3 times that of a single wear mechanism, and it is one of the key hidden threats to impeller life.

Analysis of Wear Mechanisms

Under complex loading and varying working conditions, the wear behavior of composites exhibits highly nonlinear characteristics, especially when the proportion of reinforcing phases (e.g., SiC particles), interfacial bonding conditions, and external working conditions (e.g., temperature and rotational speed), the overall wear resistance of the material will alter dramatically. To profoundly comprehend the reliability and wear failure mechanisms of composite components like impellers under severe service conditions, this section describes the key factors influencing the wear process from several aspects and reveals the wear evolution law under their synergy effect.

Dominant Role of Particle Volume Fraction in Wear Behavior

Volume fraction of particle-reinforcing phases is the primary parameter that dominates the wear performance of composites. When volume fraction is low (<10%), the dispersing of hard particles such as SiC is loose, and their load-carrying and anti-wear function for the matrix metal is not evident. The wear process is still dominated by metal adhesion wear and fatigue wear, exhibiting a matrix-controlled continuous wear state. As the volume fraction increases up to 10%–20%, particles form a synergistic support network, which not only has the capability to effectively disperse frictional heat and contact loads but also is able to construct a stable “wear surface barrier,” in this way reducing the wear rate and preventing micro-crack propagation, in the form of a stable and uniform material removal mode. When the volume fraction is increased further to more than 25%, although theoretically the wear resistance is enhanced, the particle distance is too close, easily leading to local accumulation or interface stress concentration, causing brittle fracture or debonding of particle agglomeration areas, instead of causing spalling or brittle wear behavior. Therefore, ensuring a reasonable particle volume distribution range is the key to high wear resistance.

Bidirectional Influence of Interfacial Bonding Strength on Anti-Wear Performance

The interfacial bonding strength between particles and the matrix directly affects the overall toughness and anti-wear stability of the material. If interfacial bonding is too strong, hard particles such as SiC are not easily (debonded) from the matrix under impact or high-speed sliding loads, but stress concentration is likely to occur in the interfacial zone, causing brittle fracture of the particles themselves and thereby generating micro-crack sources and affecting the overall structural integrity of the material. Conversely, if the interfacial bonding force is too small, particles will debond under tensile or shear stress, and micro-holes or surface pits remain, as new stress concentration points, further causing aggravated wear. Therefore, the selection of surface modification or coating technologies with moderate interfacial bonding energy that can form a dense transition layer is an effective means of enhancing the interfacial strength of composites and improving wear modes.

Synergistic Effect of Rotational Speed and Temperature

In actual working conditions, the thermo-mechanical coupling effect that the material undergoes is an important factor that affects wear behavior. Rotating at high speed will cause the friction interface temperature to increase abruptly, and the matrix material locally loses its strength due to thermal softening. In such a case, the reinforcing phase particles have to bear a larger proportion of the load and are therefore prone to fragmentation or interfacial debonding. Conversely, excessively high temperatures will activate the oxidation reaction of the matrix, which causes oxidation delamination of the initially stable interfacial zone, thereby deteriorating the particle fixing ability. In addition, the temperature rise process will also enhance the stress difference caused by thermal expansion mismatch, and micro-damage will be accumulated between particles and matrix. Therefore, when designing wear-resistant impeller material systems, one needs to consider the thermal response behavior under different rotational speeds and optimize them by combining technical paths such as real-time temperature control and interface stabilization.

Accelerated Damage Mechanism of Hard Particles in External Media

During actual service, impellers will typically operate in media containing solid particles, such as silica sand in seawater, Fe₃O₄ impurities in industrial media, etc. Such foreign bodies with high hardness will directly contact the material surface during high-velocity flow, building up significant scraping, plowing, and micro-crack accumulation effects, significantly accelerating the wear rate. When these foreign particles form a “squeezed state” contact with SiC reinforcing particles, they can also microscopically change the local stress state, leading to the local spalling of the composite, deepening of grooves, and interlayer degradation of the structure. Therefore, in the structural design of wear-resistant structures, apart from optimizing the material system itself, environmental adaptation designs such as surface coating and ceramic coating must be considered with a view to enhancing their resistance to damage in complex media.

Optimization Suggestions and Life Extension Strategies

Aiming at the problems of particle debonding, interfacial damage, and thermally induced wear that will occur in composite impellers under complex working conditions, it is necessary to carry out overall optimization from a number of links such as material source design, heat treatment control, surface strengthening, and operation maintenance to improve wear resistance and increase service life effectively. The following five life extension measures completely consider the double challenges of material internal structure and service environment, with feasibility and engineering application value.

Material Design Optimization

- Control SiC particle size (5–10 μm) and volume fraction (around 15%) to achieve the optimum strength-toughness combination.

- Employ coating encapsulation of SiC particles to enhance the interfacial bonding strength.

Heat Treatment Process Control

- Apply T6 tempering treatment to the matrix to achieve improvement in hardness and stability of the interfacial transition zone without embrittling the heat-affected zone microstructure.

Surface Strengthening Methods

- Apply technologies such as plasma spraying and laser cladding for creating wear-resistant surface layers to reduce the impact of particle debonding on impeller performance.

Lubrication and Cooling Optimization

- Utilize self-lubricating materials or forced cooling for pump or compression systems to lower peak friction temperature and prevent exacerbated wear due to exceedingly high temperatures.

In-Service Monitoring Mechanism

- Develop a real-time monitoring system for friction status, sense vibration, temperature, or friction sound signals, presage wear status in advance, and realize preventive maintenance.

Conclusion

Silicon carbide-reinforced aluminum matrix composite impellers possess superior lightweight and wear-resistance, but the complex material structure predetermines that they will suffer the cross-action of multiple wear mechanisms during service. By means of thorough understanding of wear behaviors such as particle debonding, interfacial fatigue, and micro-cutting, scientific basis can be provided for impeller structure optimization, process improvement, and life prediction. In the future, the integration of simulation modeling and experimental data into a multi-factor coupled wear model will help to provide theoretical and technical support for the wide application of SiC/Al composites in high-performance impellers.