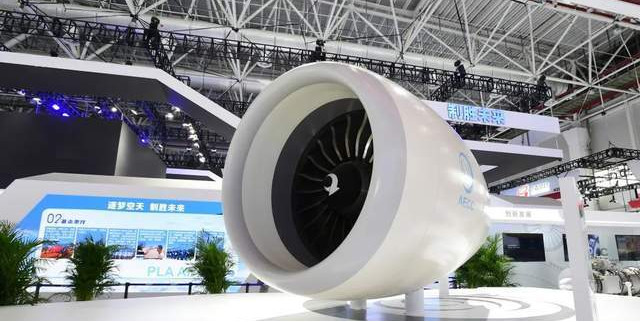

Being a high-integration, high-reliability, high-precision power system, the central component of the aero-engine—impeller—does not only carry out the central process of energy conversion but also its process quality and assembly have direct influences upon the overall aerodynamic performance, reliability, and lifecycle cost of the engine. In recent years, as multi-model parallel manufacturing and small-batch, rapid delivery have become the norm, customers have increased stronger demands on the delivery cycle of impellers. Especially in military product delivery, timely delivery, quality inspection, and traceability have become essential assurance indicators.

Introduction

As a technical and in-house engineering personnel responsible for the implementation of related projects, I well appreciate that any change in a process node during the manufacturing process of impellers, inconsistency of measurement errors, or delay in supply chain can contribute to a systematic variation in the entire delivery schedule. Consequently, how to design a closed-loop on-time delivery warranty system from planning to execution, from process to quality, and from production to supply has become the core issue to promote enterprise transformation and upgrading and enable rapid delivery of aviation impellers.

Core Challenges Facing On-Time Delivery of Aviation Impellers

In sophisticated manufacturing scenarios, aero-engine impellers, as typical complicated key components, possess a long production period, various processes, and extremely high quality requirements. On-time delivery, in addition to being a signal of delivery, is also a sign of an overall ability of an enterprise’s planning ability, manufacturing flexibility, and supply chain synchronization. By observing and monitoring a number of projects, we have come to summarize five fundamental issues in the current impeller delivery process, which are intercausal and interlinked and are the main cause of limiting delivery stability:

Structural Contradiction Between Plan Rigidity and Execution Flexibility

Traditional manufacturing firms normally implement a monthly main scheduling-based planning system. While this planning framework is quite inflexible and supportive of resource planning as a whole and goal decomposition, it is slow to react to uncertainties in the production location. Especially in impeller manufacturing, when the emergencies such as key equipment maintenance, tool failure, measurement re-do, or outsourcing slippage occur, the system lacks a rescheduling flexibility option that often results in gapping of plans—”the first and last plans are identical, but there are constant gaps in the middle”—followed by idle resources and mis-scheduling. Technically, this is a typical phenomenon of the “plan-driven” mechanism when it lacks the “closed-loop execution feedback” system, an urgent state to be eased by digital scheduling systems and rolling planning logic.

Process Bottlenecks Restricting Delivery Stability

The aviation impeller manufacturing process includes a number of technical links such as five-axis linkage high-precision machining, heat treatment, dynamic balance test, and surface hardening. These operations not only are technically sophisticated but also require concentrated resources. For example, dynamic balance test phases and vacuum heat treatment facilities usually are few in quantity due to huge investment and maintenance expenses, and have a tendency to be scheduling bottlenecks during times of high tasks. Besides that, long process switching time and great dependence on operators limit the improvement of resource utilization even further, and losses in efficiency result due to “mismatch between man-machine processes”. Capacity scheduling of bottleneck processes, pre-established redundant resources, and effective changeover processes are thus the order of the day to improve delivery flexibility.

Insufficient Supply Chain Collaboration Capabilities

The material system used to produce impellers is diverse. Core blanks such as forgings and precision castings would rely on unified buying by the group or outsourcing processing, which suffer from long cycles, slow response, and low transparency. When issue plans are delayed, demand is unstable, or supplier coordination is low, outcomes are easily events of “plans issued but blanks not arrived”ーa discontinuous material shortage impactーputting production organizations into a passive condition with no work outcomes to process. When blanks are constructed, jobs burst intensively, again impacting bottleneck resources. We can note that the supply chain issues not only affect material but also bring chain effects into the overall production rate and delivery balance.

Weak Digital Monitoring Means

Although most manufacturing companies have the fundamental ERP or MES in place, in the actual factory of high-value components such as impellers, data acquisition for key processes remains manual documentation with no real-time awareness capabilities for core factors such as equipment condition, process parameters, and tool life. Aberrations such as processing errors and scheduling lags can typically be discovered at the output only, resulting in late reactions and astronomical correction costs. Especially with no digital monitoring for these high-risk processes such as five-axis precision machining and heat treatment curve control, it is harder to construct an effective closed-loop chain of “problem early warning—decision intervention—execution adjustment”, further degrading the general controllability of the production system.

Quality Measurement Errors Causing Repeated Delivery Operations

Quality is the root bottom line of impeller delivery, and consistency and accuracy of the measurement system are key pillars of quality control. At present, due to the difficulty in achieving highly repeatable non-contact measurement for complex free-form surface structures, as well as system errors between the testing equipment, fixture positioning errors, and operator comprehension drifts, measuring results have no credibility, having a tendency to cause a vicious cycle of “rework after measurement—remeasurement—readjustment”. Especially in thin-walled blades and blade root surfaces, these discrepancies among different measuring results can be up to 30~50μm, severely restricting final assembly accuracy and delivery progress.

Architecture of On-Time Delivery Assurance System Construction

Based on the above challenges, “Aviation Impeller On-Time Delivery Assurance System” constructed in this paper is “process collaboration as the main line, data-driven as the core, and risk closed-loop as the support”, and its architecture can be decomposed into five basic modules:

- Lean planning management mechanism

- Process bottleneck identification and mitigation strategies

- Multi-level supply chain collaboration control

- Full-process digital process monitoring system

- Abnormal response and risk control closed-loop mechanism

In addition to prioritizing the timely completion of delivery nodes, this mechanism further emphasizes dynamic collaboration and real-time monitoring functions within the process for the sake of continuous delivery cycle optimization with quality stability.

Key Module Implementation Strategies and Practical Paths

To ensure on-time delivery and controllability of the aviation impeller process is an actuality, relying on scheduling tables and controlling progress nodes alone is far from enough. It is our strong belief that assurance competencies for delivery are to be developed systematically across several dimensions that include primary modules such as planning arrangement, process capability partnership, supply chain connection, monitoring the production process, and abnormal response mechanisms. Referring to actual project experience and digital transformation paths, the following action strategies have been devised with a view to improving systematically delivery reliability and responsive scheduling capacity:

Lean Planning Management Mechanism

Planning uncertainty is typically the root cause of delivery delays. To this end, we have established an integrated scheduling system of “master plan + rolling sub-plans”. The master plan creates medium- and long-term production rhythms, while rolling plans are updated on a 24-hour basis to respond reactively to site variations. A model of constrained scheduling is built into the scheduling algorithm, taking into account extensively multi-dimensional bottlenecks of equipment availability, staff rosters, tool life, and fixture use. On the other hand, a kanban system is computerized to show the execution status of plans in real-time to the frontline of the workshop. Important metrics such as achievement rate and lag hours of bottleneck process are displayed in full view, thereby greatly reducing the closed-loop time of “plan communication—execution—response”.

Process Bottleneck Coordination and Capability Improvement

At the execution level, five-axis linkage precision machining and dynamic balance testing are the links with the highest delivery risk. By OEE (Overall Equipment Effectiveness) analysis, we found problems of low changeover efficiency of equipment and too much tool waiting time. In response, we put in a tool quick-change system and a standard process template switching device, and reduced the average cycle per order by 18%. In addition, to respond to peak task periods, redundant equipment for master processes are in standby, and a “multi-skilled worker” pool and cross-process rapid scheduling system are established, substantially enhancing production flexibility.

Multi-Level Supply Chain Collaboration Control

Material supply stability is a prerequisite for on-time delivery. We use a “double-cycle + kanban pull” mode in supply chain management: on the one hand, routine replenishment cycles are established according to the master plan; on the other, dynamic pull replenishment is triggered when MES system kanban feedback is obtained. For key outsourcing units such as heat treatment and surface treatment factories, we enter into node responsibility contracts and conduct monthly on-time delivery rate assessments. For those who are outside the norm, there is another resource pool that is established to offer emergency response capability in some unexpected situation.

Digital Process Monitoring System

Unexpected irregularities or process delays are inevitable in the production process. To correct this, we delve deeply into how to integrate the MES system and RFID batch traceability technology to realize full-process node monitoring for all impellers from blank to final inspection. In particular, “path lag warning thresholds” are set for large processes (for example, five-axis rough machining and accurate machining). After 8 hours, an automatic warning is released and the master planning system is linked to replan the follow-up production. In addition, by adding process parameter monitoring interfaces, the system can detect equipment running status in real time, providing first-hand data for follow-up fault analysis and continuous optimization.

Risk Identification and Abnormal Closed-Loop Control

Unanticipated risks in the manufacturing process have a tendency to be caused by being inexperienced or slow in responding. In order to enhance systematicness of abnormal responses, we constructed an “impeller manufacturing risk knowledge base,” classifying common failure modes in past projects and setting up an FMEA model (Failure Mode and Effects Analysis). At the same time, an emergency resource pool is created, such as immediate programming assistance, substitute calls for tooling, night shift tool change-over plans, etc., building a rapid-response chain of “problem identification—impact assessment—resource mobilization—closed-loop verification”, which has greatly improved the organization’s ability to deal with sudden abnormalities.

Case Practice: A Certain Type of Low-Pressure Turbine Impeller Delivery Improvement Project

Project Background

The customer ordered 45-day delivery of the first batch of a given low-pressure turbine titanium alloy impeller type. The product batch number in each case ranges from 5 to 10 pieces, requiring adaptation to variable-batch, short-cycle, and high-speed delivery conditions.

Core Strategies and Implementation Effects

| Strategy | Effect |

| Process and tooling modularization | Changeover time reduced by 20% |

| Night “lights-out factory” operation | Realized 24-hour uninterrupted processing |

| Impeller delivery management platform | Real-time status visibility, task locking |

| Weekly node review system | Progress deviations warned in advance |

Finally, the average delivery cycle was reduced from 62 days to 41 days, first-piece on-time shipment rate was increased to 96%, customer satisfaction scores were enhanced from 3.9 to 4.7, and the plan implementation fluctuation range was reduced to ±1.2 days.

Supplement to Standards and Delivery Mode Optimization Ideas

Besides systematic guarantees, optimization of delivery test-run mode is also necessary for the shortening of the impeller delivery cycle. Currently, the mainstream domestic practice adopts “two installations and two tests” of delivery acceptance, but it consumes much time and resources. According to such standards as GJB 241A-2010 and JSSG-2007, for products of good quality stability and mature design of impellers, we can make a “one installation and one test” delivery test run strategy, which can significantly improve the efficiency of delivery while guaranteeing the premise of quality assurance.

By means of sampling verification, “phased quality problem attribution”, and so on, we are able to scientifically determine the feasibility of mode change in delivery and risk control capability, and gradually realize a low-cost, high-efficiency, and replicable delivery guarantee mechanism.

Conclusion

As a fundamental component of an aero-engine, the capability to provide impellers in time not only reflects an enterprise’s overall manufacturing capacity but also a key node in China’s independent and controllable power system of its aviation industry. It is only through developing an assurance system of process-led delivery, backed by evidence and with shut loops of joint working, and possessed of technical in addition to management capability, that we can finally realize the dreams of “rhythmic delivery, assured quality, and traceable processes.”.